In the rapidly evolving landscape of construction, the demand for reliable and efficient machinery has never been higher. As projects grow in scale and complexity, understanding the nuances of used tower cranes has become essential for contractors aiming to optimize their investments. Among the various options available in the market, the Xcmg Used Tower Crane stands out as a popular choice for many construction teams, appreciated for its cost-effectiveness and operational efficiency.

This article aims to delve into the top insights regarding used tower cranes, specifically focusing on characteristics that define their performance, durability, and value for money. With a keen eye on market trends, we will explore how the selection of a used tower crane can significantly impact overall project timelines and budgets. Additionally, we will discuss key considerations when acquiring such equipment, ensuring that construction professionals are well-informed and equipped to make strategic decisions. From understanding the technological features to evaluating maintenance histories, these insights will serve as a valuable guide in navigating the realm of used tower cranes for construction projects.

The used tower crane market is poised for significant growth in 2025, driven by the increasing demand for cost-effective construction solutions. According to industry reports, the global market for used tower cranes is expected to exhibit a compound annual growth rate (CAGR) of 6.5% from 2023 to 2028. This growth is primarily attributed to the rising trend of urbanization and the expansion of infrastructure projects worldwide. As construction companies seek to balance efficiency and budget constraints, the utilization of used tower cranes offers a practical solution, allowing access to high-quality equipment at a fraction of the cost of new models.

One of the emerging trends in the used tower crane market is the focus on sustainability. Many construction firms are increasingly prioritizing environmentally friendly practices, leading to a surge in demand for refurbished equipment that meets modern performance standards. Reports indicate that around 40% of construction firms are actively seeking used cranes that have been upgraded with newer technology, ensuring compliance with stringent environmental regulations while minimizing their carbon footprint. This trend not only contributes to cost savings but also aligns with global sustainability goals.

Tips: When considering the purchase of a used tower crane, conduct thorough inspections to assess the condition and operational history of the equipment. Ensure that proper documentation is available, including maintenance records and compliance certificates. Additionally, seek reliable suppliers who offer warranties or service agreements to enhance the value and security of your investment.

| Insight Category | Key Insights | Market Trend | Forecast (2025) |

|---|---|---|---|

| Demand Growth | Increased construction activities post-pandemic | Rising demand for urban infrastructure | +15% growth in used tower crane sales |

| Sustainability | Enhanced focus on eco-friendly equipment | Shift towards energy-efficient models | 20% selection of eco-friendly cranes |

| Technology Integration | Adoption of smart crane technologies | Increased use of IoT and automation | 30% of cranes equipped with smart technologies |

| Market Accessibility | Easier access to used cranes via online platforms | Growth in e-commerce-related equipment sales | 50% increase in online listings |

| Safety Standards | Heightened safety regulations for crane operations | More rigorous inspections and certifications | Compliance rate of 90% by 2025 |

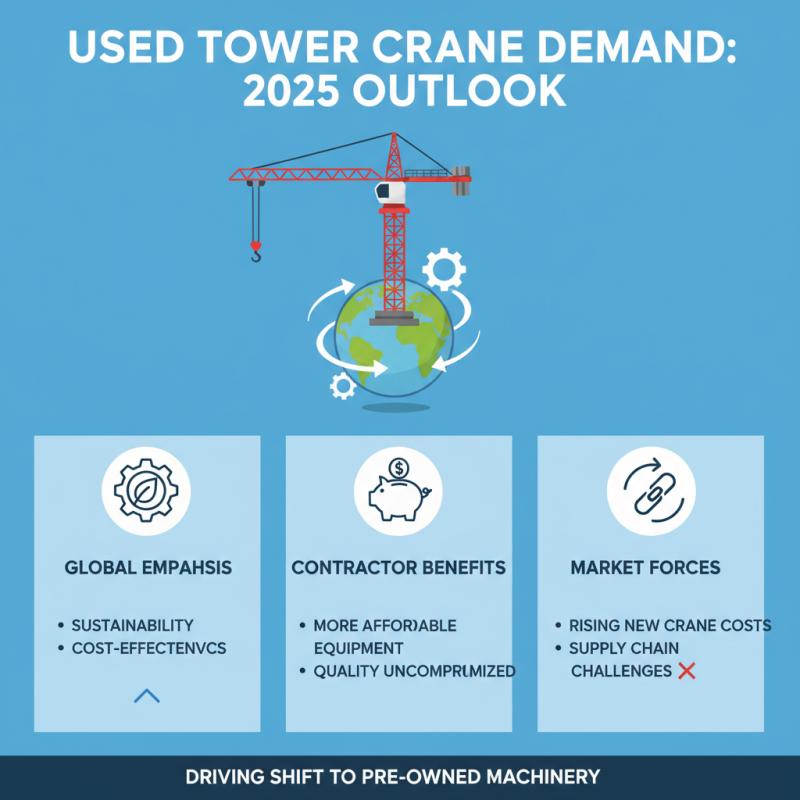

In 2025, the demand for used tower cranes in construction projects is poised to be influenced by several key factors. Firstly, the ongoing global emphasis on sustainability and cost-effectiveness is driving contractors to seek pre-owned equipment. Used tower cranes offer a more affordable option without compromising on quality, making them appealing to budget-conscious firms facing economic pressures. This trend is further accelerated by the rising costs of new cranes and supply chain challenges that have made the procurement of new machinery increasingly difficult.

Secondly, the growth of urbanization and infrastructure development worldwide is contributing to the heightened need for tower cranes. As cities expand and construction projects become more ambitious in scale, such as high-rise buildings and large commercial spaces, the versatility and efficiency of tower cranes become indispensable. The fact that used cranes can be operational quickly after purchase further enhances their appeal, providing construction companies with the flexibility to meet tight deadlines and project demands. Consequently, these factors together create a dynamic market for used tower cranes in 2025, driven by both economic considerations and the evolving landscape of urban development.

The construction industry continues to explore the financial implications of investing in used tower cranes versus new ones. According to a recent report by Research and Markets, purchasing a used tower crane can save contractors between 20% to 40% compared to buying new equipment. This price differential is particularly significant in tight budget scenarios, where every dollar spent can impact project feasibility. For instance, an analysis in the 2023 Global Construction Equipment Market report indicated that contractors who utilized used cranes were able to allocate funds more efficiently, subsequently improving overall project margins.

Moreover, used tower cranes offer the advantage of faster depreciation compared to new cranes, which lose value at a steeper rate during their initial years. According to Statista, the first year alone can see a depreciation of up to 25% for new construction equipment. This aspect makes used cranes an attractive option for projects that may not require the latest technology or features, allowing companies to balance performance with costs. Notably, a 2024 industry analysis highlighted that many used cranes had undergone rigorous refurbishing processes, ensuring they meet safety regulations without the hefty costs associated with purchasing new units.

As the industry evolves, the turnover rate for construction equipment is increasing, with used cranes becoming more readily available. In 2023, the global market report noted a surge in the resale of equipment, driven by ongoing economic pressures. This trend signals an opportunity for project managers to capitalize on the value of used cranes, making strategic decisions that align with budget constraints while still ensuring project timelines and productivity are not compromised.

In 2025, the construction industry continues to prioritize safety regulations, especially concerning the operation of used tower cranes. Enhanced safety protocols are essential to mitigate risks associated with crane operations. Compliance with these regulations is not only a legal obligation but also a vital step toward ensuring the well-being of workers on site. As operations evolve, it is crucial for project managers and crane operators to stay informed about the latest regulations, which include regular inspections, operational training, and proper maintenance of equipment.

Tips: Conduct regular safety training sessions for all personnel involved in crane operations. This ensures that every team member is aware of the current regulations and protocols, minimizing the risk of accidents. Additionally, always keep documentation of safety checks and maintenance logs readily accessible, as this not only adheres to regulatory requirements but also boosts accountability and operational efficiency.

As the industry adapts to changing safety standards, the importance of using certified operators becomes evident. Engaging qualified professionals who are knowledgeable about current regulations can significantly enhance site safety. It's also advisable to invest in technology that enables real-time monitoring of crane operations, providing data that can help identify potential safety issues before they escalate. By prioritizing safety and regulatory compliance, construction projects can not only protect their workforce but also enhance overall productivity and efficiency.

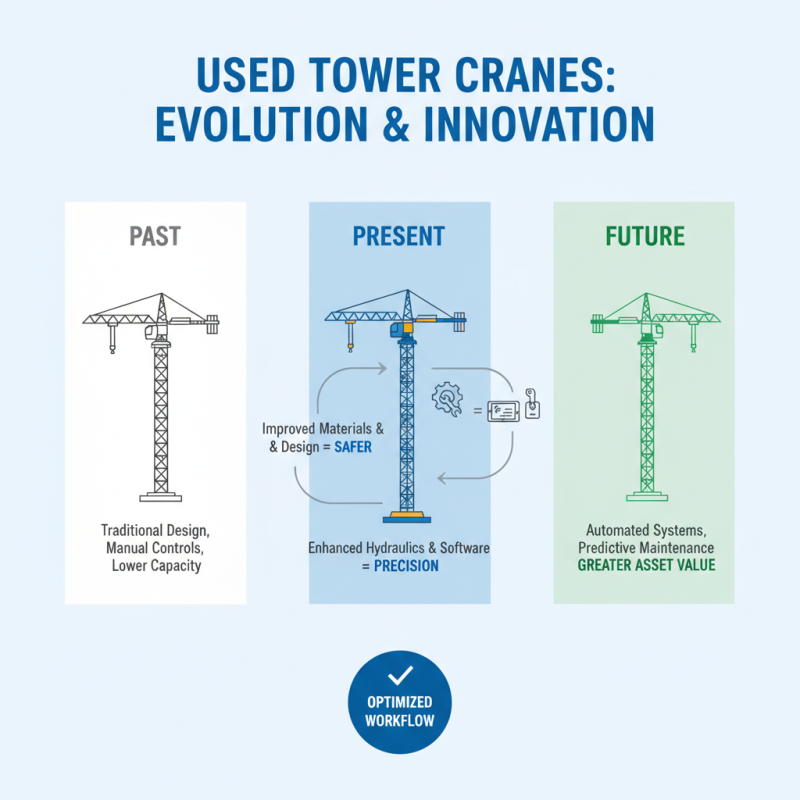

The evolution of used tower cranes in the construction industry has been significantly shaped by technological advances, positioning them as valuable assets for modern projects. Innovations in design and materials have improved the structural integrity and efficiency of these cranes, making them safer and more reliable. Enhanced hydraulic systems and control software enable operators to manage loads with greater precision, reducing the risk of accidents and optimizing workflow on construction sites.

Furthermore, the integration of smart technologies has revolutionized the operational capabilities of used tower cranes. IoT devices equipped with sensors now provide real-time data on performance metrics, allowing for predictive maintenance and minimizing downtime. Advanced telematics systems enable remote monitoring, giving project managers insights into crane usage patterns and performance analytics. This data-driven approach not only enhances productivity but also contributes to informed decision-making regarding equipment utilization, ultimately driving cost savings for construction projects. As technology continues to advance, the value of used tower cranes will only grow, making them an indispensable element in the quest for efficiency and safety in construction.