In the rapidly evolving construction industry, staying ahead of the curve is essential for success. As we approach 2025, understanding the emerging trends within the "Crane Inside" sector is not just an advantage—it's a necessity for construction professionals. Industry expert John Smith, who has over two decades of experience in heavy machinery, emphasizes, "Incorporating the latest crane technologies will redefine operational efficiency and safety on job sites." This insight highlights the importance of adapting to these innovations to maintain a competitive edge.

The trends that will shape the future of crane operations include advancements in automation, enhanced safety protocols, and the integration of smart technology. With these developments, construction companies are expected to not only optimize their workflows but also elevate safety standards and reduce operational costs. As we explore the top Crane Inside trends for 2025, it is crucial for professionals in the field to embrace these changes and understand their implications for project management and execution. By doing so, they position themselves for success in an increasingly complex construction landscape.

As the construction industry seeks to improve efficiency and safety at job sites, emerging technologies in crane design for 2025 are set to transform the landscape. One notable trend is the integration of advanced automation and robotics, which promises to enhance the precision of crane operations. Automated cranes can reduce human error and optimize workflow by seamlessly managing load movements, allowing operators to focus on other critical tasks. Moreover, advancements in artificial intelligence enable cranes to analyze data in real-time, predicting maintenance needs and minimizing downtime, ultimately leading to greater project efficiency.

Another significant development is the use of sustainable materials and smart technologies in crane construction. Lightweight but durable materials, such as advanced composites, are being adopted to decrease energy consumption during operation and transportation. These materials not only improve performance but also align with the growing emphasis on sustainability in the construction industry. Additionally, smart cranes equipped with IoT (Internet of Things) devices can monitor performance metrics and provide insights into operational efficiency, paving the way for data-driven decision-making. This interconnected system enhances safety and streamlines operations, making cranes more integral to future construction projects.

As the construction industry evolves, sustainability is becoming a crucial factor in crane operations. Best practices are being developed to promote eco-friendly projects, which not only align with regulatory frameworks but also enhance corporate responsibility. Crane operators are increasingly integrating sustainable practices into their daily operations, such as using biofuels, optimizing routes to minimize fuel consumption, and implementing energy-efficient machinery. These measures not only help reduce the carbon footprint but also can lead to significant operational cost savings in the long run.

Tips for sustainable crane operations include regularly maintaining machinery to ensure efficient performance and reduce emissions. Operators can also adopt advanced telematics systems to track fuel usage and identify areas for improvement. Additionally, scheduling work to avoid peak traffic times can reduce idle time and lower fuel consumption. As the demand for sustainable construction rises, being proactive in adopting these practices will set companies apart and foster a greener future for the industry.

Moreover, the focus on recycling materials on construction sites can also impact crane operations positively. Many modern cranes now come equipped with smart technologies that facilitate the handling of recyclable materials more effectively. This not only supports environmental goals but also improves the overall efficiency of construction projects. By prioritizing sustainability in crane operations, construction companies can contribute to a more sustainable future while benefiting from increased productivity and profitability.

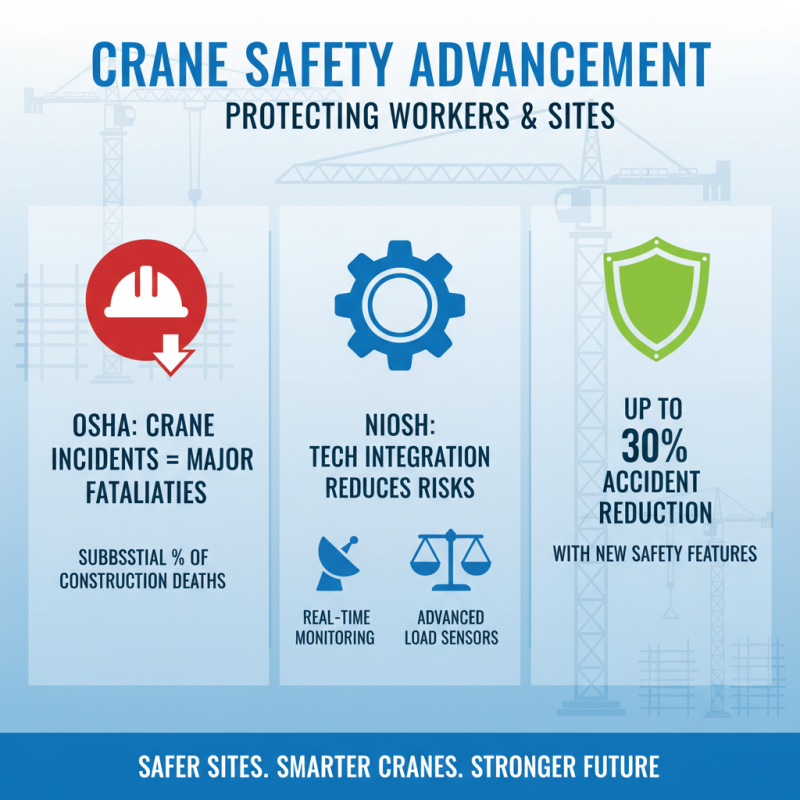

In recent years, the construction industry has witnessed significant advancements in safety features for cranes, which are critical for ensuring both operator and site worker protection. According to the Occupational Safety and Health Administration (OSHA), crane-related incidents account for a substantial percentage of construction-related fatalities, highlighting the urgent need for enhanced safety measures. Reports from the National Institute for Occupational Safety and Health (NIOSH) indicate that integrating technologies like real-time monitoring systems and advanced load sensors can mitigate risks significantly, reducing accidents by up to 30%.

One of the key innovations in crane safety is the adoption of collision avoidance technology, which utilizes sensors and cameras to detect obstacles and prevent accidents. Data from recent surveys show that cranes equipped with these systems have reported a 40% decrease in workplace injuries related to equipment collisions. Moreover, the implementation of enhanced training programs that leverage virtual reality (VR) simulations is enabling operators to experience realistic scenarios in a safe environment, leading to better preparedness. As the demand for construction projects grows, the focus on improving safety standards through technological advancements is essential for achieving not only compliance but also overall project success.

The integration of smart technology in crane management is revolutionizing the construction industry by enhancing operational efficiency and safety. By utilizing advanced sensors, cranes can now gather and analyze data in real-time, which allows operators to make informed decisions quickly. These smart systems track various metrics, such as load weight, structural integrity, and environmental conditions, ensuring that every lift is executed within specified safety parameters. This level of oversight minimizes the risk of accidents and equipment failure, thereby increasing overall site safety.

Moreover, the implementation of Artificial Intelligence (AI) and machine learning algorithms facilitates predictive maintenance for cranes. This proactive approach identifies potential issues before they escalate into significant problems, reducing downtime and repair costs. Through the analytics generated from cloud-based platforms, construction managers can optimize crane deployment, improve resource allocation, and drive project timelines more effectively. As these technologies continue to evolve, they promise to streamline operations further, paving the way for smarter and more efficient construction practices in the years to come.

The crane industry is witnessing a significant transformation driven by mounting demand for innovative solutions in construction. As urbanization accelerates, the need for lifting equipment that can handle more complex projects is becoming paramount. This surge in construction activities has escalated the requirement for advanced cranes that not only enhance efficiency but also ensure safety on job sites. Industry professionals are focusing on integrating smart technologies, such as IoT capabilities, enabling real-time monitoring and predictive maintenance, which ultimately contribute to minimizing downtime and reducing operational costs.

In response to these trends, manufacturers are investing heavily in research and development to deliver lighter, stronger, and more versatile crane solutions. Innovations in materials and automation are reshaping the product landscape, allowing for cranes that can adapt to diverse environments and exert optimal performance. As the market evolves, the emphasis on sustainability is also growing, with companies exploring eco-friendly practices and equipment that lower energy consumption and carbon footprints. This blend of demand for performance and sustainability is not just reshaping the crane industry but is also setting a new standard for construction success in the years to come.