The construction industry relies heavily on Tower Cranes for efficiency and safety. According to a report by the Global Construction Market Insights, the demand for Tower Cranes is expected to grow by 5% annually through 2026. This reflects the increasing need for vertical lifting capabilities in urban development projects. As noted by industry expert John Smith, "The right Tower Crane can make or break a project's timeline." His insight emphasizes the importance of selecting the best models.

Selecting the right Tower Crane involves considering factors like load capacity, height, and mobility. For instance, the Liebherr 630 EC-H and the Sky Crane VFR 6420 are top contenders. Their robust performance and proven reliability make them favorites among contractors. However, not all models are ideal for every project. It's essential to reflect on specific job site needs and constraints.

Even with advanced technology, some challenges persist. Issues like setup time and operator training can hinder efficiency. Investment in quality Tower Cranes is crucial, but awareness of these challenges can make a significant difference. The right choice of the Tower Crane aligns project goals with operational realities, ensuring success while navigating potential pitfalls.

Tower cranes play a vital role in modern construction. They provide the necessary lifting power for heavy materials. These cranes are often seen on construction sites, rising high above buildings. Their design allows for maximum reach and flexibility. Operators can easily maneuver materials to various heights and distances. This efficiency greatly enhances the workflow on site.

However, tower cranes come with challenges. Setting them up requires careful planning and execution. Safety is a key concern. Operators must be well-trained to manage loads effectively. Miscommunication can lead to accidents. Many sites have strict regulations regarding tower crane operation. Adhering to these is crucial for worker safety and project success.

The placement of tower cranes must be strategic. They should not obstruct other machinery or workers. Visibility is important for both operators and those on the ground. Crane coordination can become complex in busy areas. Understanding these factors can help teams avoid potential pitfalls. Regular maintenance checks ensure that cranes operate smoothly. This practice minimizes breakdowns, contributing to overall project efficiency.

When selecting a tower crane for construction, several key features demand your attention. The lifting capacity should be one of your top priorities. Understand the weight requirements of your project. A crane with inadequate lifting capacity can lead to inefficiencies and potential accidents. Additionally, consider the maximum height and radius the crane can reach. Choose a model that can adequately cover the work area.

Next, think about the ease of assembly and disassembly. Cranes should not require excessive time or complicated processes for setup. This factor can significantly impact project timelines. Moreover, assess the safety features. Look for models equipped with alarms, limit switches, and other safety mechanisms. These elements are critical for protecting workers and ensuring a smooth operation.

Lastly, analyze the crane's operational speed and controls. A faster operation can improve productivity, but it's essential to maintain safety. Balance speed with the need for careful maneuvering. Also, reflection on maintenance requirements is vital. Cranes that demand high maintenance can disrupt schedules. A thoughtful selection of these features can enhance your construction efficiency.

When choosing a tower crane for construction projects, understanding specifications is crucial. Tower cranes come in various models, each serving specific purposes. Some models excel in lifting heavy materials, while others are designed for high-rise buildings. Key specifications include maximum load capacity, lifting height, and radius reach. These factors determine a crane's suitability for different types of construction.

For example, a crane with a larger load capacity can handle more substantial building materials, which is essential for skyscrapers. Conversely, models with a shorter radius may be appropriate for smaller sites. Each model's design plays a role in maneuverability and stability. It's important to assess site conditions and project requirements. Some cranes can be cumbersome in tight spaces, limiting their application.

Additionally, user experience often reveals practical challenges. Crane operators may find specific controls unintuitive, leading to inefficient operation. Maintenance needs can be overlooked, causing downtime. Reflecting on these factors helps improve operational efficiency. Understanding each model’s strengths and weaknesses is vital for making the right choice in construction projects.

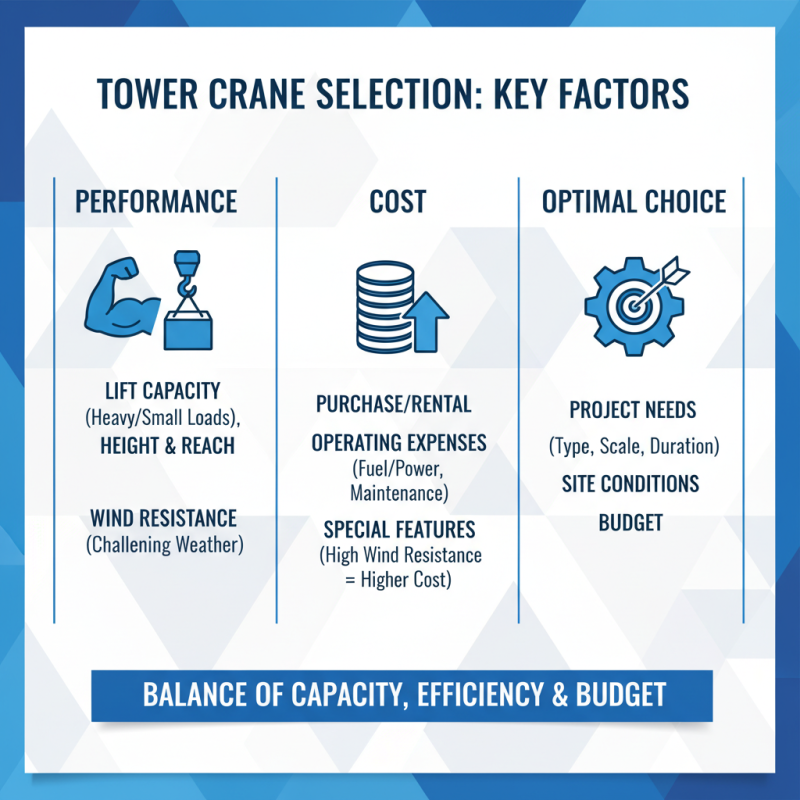

When selecting the right tower crane model for construction projects, performance and cost are key factors. Different models are designed with specific capacities and heights. Some excel in lifting heavier loads, while others are more efficient with smaller weights. For instance, cranes with high wind resistance can operate in challenging weather. However, this can also lead to increased costs.

Cost analysis shows a spectrum of price points across various models. Certain cranes may appear budget-friendly but incur higher maintenance over time. Other models have a greater upfront cost yet are built for longevity and stability. The trade-offs between operation expenses and initial investment often warrant reflection.

Performance metrics include load capacity and operational speed. Some cranes have faster lifting times, which can accelerate project timelines. However, the durability of parts can sometimes compromise speed. Understanding these dynamics helps to prioritize what is essential for each project. Choosing the right model isn't merely about cost; it also demands careful assessment of performance expectations.

Maintenance is crucial for tower cranes in construction. Regular checks prevent accidents and equipment failure. Operators should inspect components routinely. Look for wear and tear, especially in cables and gears. A small problem can lead to larger issues. Frequent maintenance ensures safety on site.

Tips: Always keep maintenance logs. Document each inspection and repair. This helps in tracking the crane’s condition. Training crew members on safety protocols is essential. Ensure they know emergency procedures. It builds confidence and awareness.

Safety considerations cannot be overlooked. Crane operators must adhere to guidelines. They need a clear understanding of load limits. Overloading can cause structural failure. Regular safety drills will keep everyone prepared. Communication on site is vital for preventing accidents. Ensure that workers can signal effectively.

Tips: Place warning signs around the crane area. Visibility is key during operations. Avoid distractions while operating or supervising the crane. A moment of inattention can lead to dangerous situations. Focus on creating a safety-first culture among your team.

| Model | Max Load Capacity (tons) | Max Height (m) | Boom Length (m) | Operating Radius (m) | Safety Features | Maintenance Frequency |

|---|---|---|---|---|---|---|

| Model A | 10 | 50 | 60 | 45 | Anti-collision system, Load moment indicator | Monthly |

| Model B | 12 | 55 | 75 | 50 | Emergency stop, Motion limit switches | Bi-Monthly |

| Model C | 15 | 70 | 80 | 55 | Overload protection, Wind speed monitor | Quarterly |

| Model D | 8 | 40 | 50 | 30 | Safety alarms, Power failure protection | Monthly |

| Model E | 20 | 60 | 90 | 60 | Incremental loading, Remote monitoring | Quarterly |