When embarking on a construction project, the choice of equipment can significantly impact both efficiency and cost. One crucial piece of machinery that stands out in the industry is the Used Liebherr Tower Crane. As renowned expert in construction machinery, John Smith, states, "Investing in a used Liebherr Tower Crane not only saves money but also ensures that you have the reliability and performance needed for complex projects." This sentiment reflects the growing trend among contractors to opt for quality pre-owned equipment to meet their operational needs.

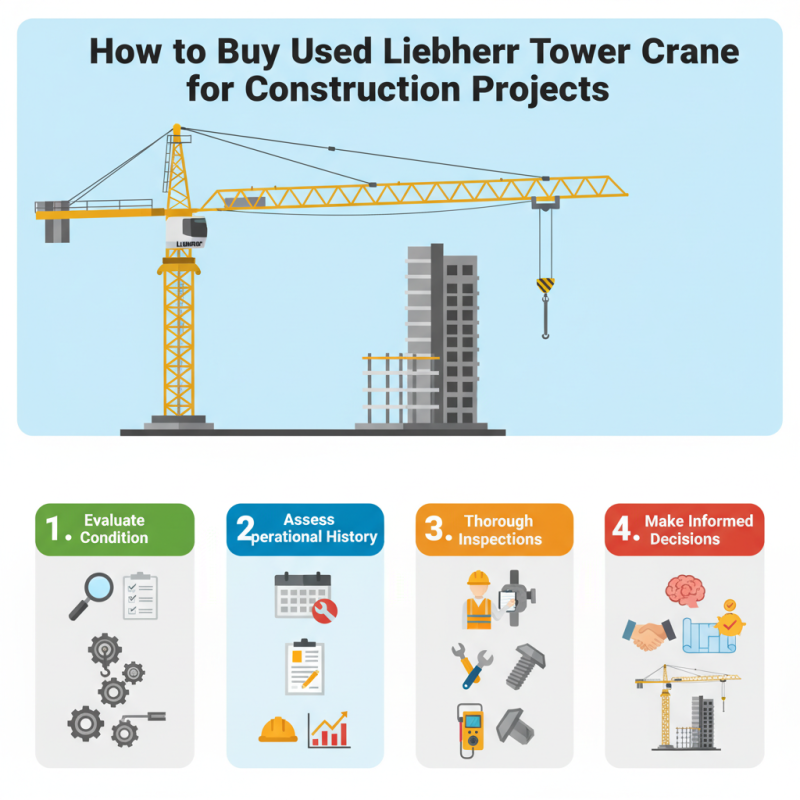

The market for used Liebherr Tower Cranes offers a variety of options, making it imperative for project managers and contractors to understand the intricacies of this purchasing process. From evaluating the crane’s condition to assessing its operational history, there are numerous factors to consider that can safeguard your investment and enhance productivity on-site. By leveraging expertise and thorough inspections, you can make informed decisions that align with your project goals and budget constraints. Ultimately, incorporating a Used Liebherr Tower Crane into your construction arsenal may very well be the key to successful project execution and competitive advantage.

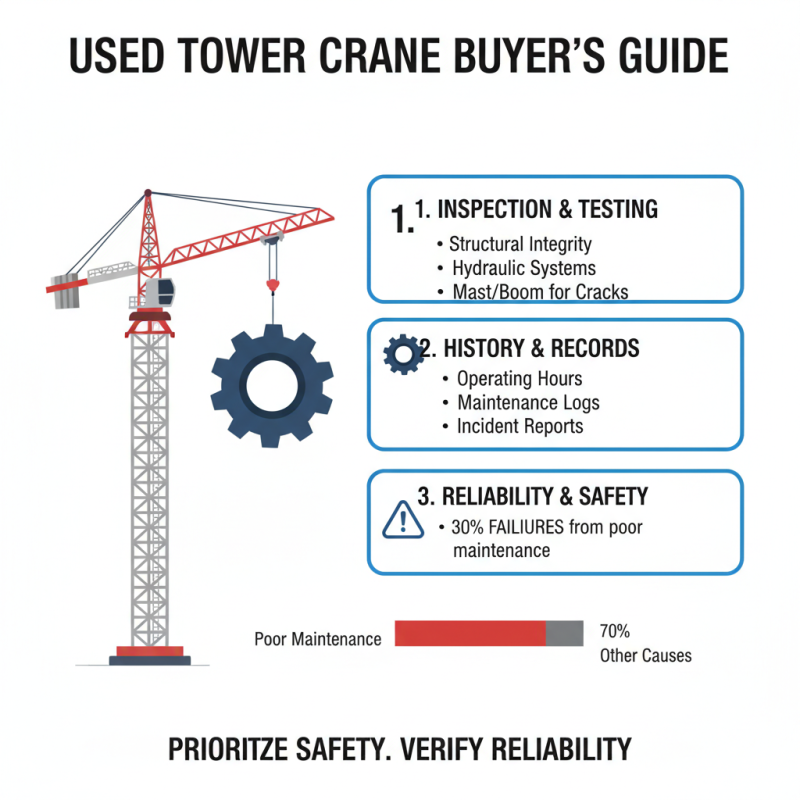

Assessing the condition of used Liebherr tower cranes is crucial for ensuring the safety, efficiency, and longevity of construction projects. First and foremost, it’s essential to conduct a thorough inspection of the crane's structural integrity. Look for signs of wear, corrosion, or damage in critical components such as the boom, base, and mast. Industry reports indicate that around 30% of construction machinery failures stem from neglecting routine maintenance checks. Therefore, reviewing the maintenance history of the crane can provide insights into its operational reliability.

In addition to physical inspections, evaluating the crane's operational hours is vital. The average lifespan of a tower crane is typically between 10 to 15 years, depending on usage and maintenance. When considering a used Liebherr tower crane, cranes with less than 5,000 operating hours are often viewed as having considerable residual value, while those exceeding 10,000 hours may require more extensive refurbishments. Furthermore, it’s essential to test the crane's functionality under load conditions to ensure it operates within safe limits and adheres to industry safety standards. Reports show that cranes that undergo rigorous testing show a 40% increase in operational efficiency and reduced downtime on construction sites.

| Model | Year of Manufacture | Operating Hours | Condition | Price (USD) |

|---|---|---|---|---|

| Liebherr 81K.1 | 2015 | 3,500 | Good | $110,000 |

| Liebherr 100 EC-B 10 | 2018 | 2,200 | Very Good | $140,000 |

| Liebherr 132 EC-H 40 | 2016 | 4,000 | Fair | $95,000 |

| Liebherr 150 EC-B 12 | 2017 | 3,000 | Good | $125,000 |

| Liebherr 112 EC-H 40 | 2019 | 1,800 | Excellent | $155,000 |

When considering the purchase of a used tower crane for construction projects, it is crucial to focus on specific key specifications that can significantly impact performance and safety. First, assess the lifting capacity of the crane, as this will determine how much weight it can handle at various heights. Cranes come with different load charts, so verifying the maximum load and ensuring it aligns with your project requirements is essential. Additionally, consider the jib length, which affects the reach of the crane and its ability to maneuver in tight spaces.

Another important specification to evaluate is the operating condition of the crane, including the age, maintenance history, and any repairs it has undergone. Inspect the hydraulic system, electrical components, and overall structural integrity to gauge reliability. Cranes that have been well-maintained often offer greater longevity and lower operational risks.

**Tip:** When negotiating the price, factor in any necessary repairs or upgrades that may be needed to bring the crane to optimal working condition. Additionally, always request a thorough inspection report and consider hiring a professional to help assess the crane's operational state before finalizing the purchase. This ensures you make a sound investment that supports the safety and efficiency of your construction projects.

When purchasing a used tower crane, understanding its market value and depreciation is essential for making an informed decision. Typically, tower cranes like those manufactured by prominent brands undergo significant depreciation in their initial years, with studies indicating that these assets can lose about 20-30% of their value within the first three years of operation. This rapid depreciation often results from the high capital costs associated with new cranes, combined with the advancements in crane technology that make older models less desirable.

Market value is influenced by various factors, including the crane’s age, condition, and usage history. Research shows that the average lifespan of a tower crane can extend beyond 20 years, but the resale value significantly declines after the first five years, averaging around 40-50% of its original purchase price. Additionally, equipment inspection reports, maintenance records, and compliance with safety regulations play a crucial role in determining value. Buyers should also be wary of regional market trends, as these can significantly affect demand and pricing in different areas. With careful analysis and a focus on depreciation metrics, buyers can secure a used tower crane that meets their project needs without overpaying.

When searching for reliable sellers of used tower cranes for construction projects, it's essential to prioritize transparency and reputation. Begin your search by exploring online marketplaces and specialized construction equipment websites that feature listings from verified sellers. These platforms often have ratings and reviews that can give you insight into the seller's reliability and the quality of their equipment. Look for detailed descriptions, specifications, and photographs that will help you assess the condition of the cranes before making a purchase.

Additionally, attending industry trade shows and networking events can be beneficial in connecting with reputable vendors. These gatherings provide an excellent opportunity to meet sellers in person and inspect the equipment firsthand. Engaging in discussions with industry professionals can also lead to valuable recommendations and insights into trustworthy sellers. Always consider seeking out sellers who offer after-sales support, warranties, or guarantees on their equipment, as these can further ensure that you are making a secure investment.

When considering the purchase of a used tower crane, particularly from reputable manufacturers, it’s crucial to conduct a thorough inspection and testing process to ensure the equipment’s reliability and safety. Research indicates that nearly 30% of all construction machinery failures are attributed to inadequate maintenance or hidden damages. Therefore, potential buyers should prioritize a detailed assessment of the crane's structural integrity, operating history, and maintenance records. Consider checking for signs of wear and tear, including cracks in the mast and boom, as well as the overall condition of the hydraulic systems.

During the testing phase, it’s essential to evaluate the crane's performance under load. According to industry standards, a used tower crane should operate smoothly without excessive noise or abnormal vibrations when tested at various load capacities. It is recommended to verify the load chart to confirm that the crane meets your project specifications. Additionally, ensure that safety features, such as limit switches and alarms, are functional. Engaging a certified technician for a complete evaluation can also provide invaluable insights into potential issues that may not be immediately visible, ultimately helping you make an informed purchase decision.