When considering the purchase of a used tower crane, particularly the Used Liebherr Tower Crane, several crucial factors must come into play to ensure a sound investment. The complexities inherent in selecting a tower crane, which is essential for various construction projects, require a comprehensive understanding of not just the machinery itself but also the overall market dynamics. Buyers need to assess the equipment's condition, operational history, and maintenance records, along with the reputation of the seller. By doing so, they can avoid potential pitfalls that could affect project timelines and budgets.

In addition to mechanical reliability, it’s vital to consider the operational capacity and specifications of the Used Liebherr Tower Crane relative to project requirements. Determining whether the crane can meet the specific lifting heights and weights required for your project is key to ensuring efficiency and safety on-site. Furthermore, understanding the regulatory and compliance factors associated with used cranes is essential to avoid any legal challenges after acquisition. This introduction aims to highlight these critical aspects, equipping potential buyers with the knowledge necessary to make informed decisions as they navigate the used crane market.

When purchasing used tower cranes, it’s crucial to evaluate key specifications that directly impact both performance and safety. One of the most significant factors is the crane's load capacity, which typically ranges from 1 to 18 tons for general construction use. According to a report by MarketsandMarkets, the demand for tower cranes is expected to grow steadily, with a focus on those that can handle heavier loads and provide enhanced operational efficiency. Buyers should carefully check the rated load capacity indicated on the crane's specifications and match it against the potential lifting requirements of their projects.

Another vital specification to consider is the boom length. The reach of the crane affects the area it can cover on a construction site, influencing the number of cranes needed for efficient operation. A typical tower crane can have a horizontal reach of anywhere between 40 to 80 meters, with some specialized models extending even further. Furthermore, assessing the crane's age, maintenance history, and adherence to safety standards is essential. Data from the International Institute of Crane and Rigging indicates that cranes older than ten years may require more frequent inspections and might not meet current safety regulations. By thoroughly evaluating these specifications, buyers can ensure they invest in a tower crane that meets their operational needs while prioritizing safety and reliability.

| Factor | Description | Importance | Average Cost (USD) |

|---|---|---|---|

| Age of the Crane | The manufacturing year and how many years it has been in use. | High | $25,000 - $50,000 |

| Maximum Load Capacity | The weight the crane can lift at maximum efficiency. | Critical | $30,000 - $60,000 |

| Boom Length | The length of the crane boom affects reach and load capabilities. | High | $20,000 - $45,000 |

| Maintenance History | Records of repairs and regular servicing can indicate reliability. | Very High | $15,000 - $35,000 |

| Compliance with Safety Standards | Must meet local and international safety regulations. | Essential | $10,000 - $25,000 |

| Type of Control | Remote, fixed, or smart control systems can enhance usability. | Moderate | $5,000 - $15,000 |

| Modifications | Additions or changes made to the crane can affect its value. | Low | $3,000 - $12,000 |

| Previous Usage | How the crane has been previously utilized can indicate wear. | Moderate | $10,000 - $20,000 |

| Resale Value | Expected resale value can indicate overall condition and market demand. | High | $20,000 - $40,000 |

When considering the purchase of a used tower crane, understanding its history and prior usage is crucial. Tower cranes have been instrumental in urban construction projects, evolving significantly since their inception in the early 20th century. A report by the International Tower Crane Association highlights that approximately 30% of tower cranes currently in operation are over 15 years old, indicating a substantial market for pre-owned cranes. This age factor necessitates thorough evaluations, as the conditions under which these cranes were operated can heavily influence their reliability and safety.

Moreover, usage history plays a pivotal role in assessing the condition of a used tower crane. A study conducted by the Construction Industry Research and Information Association suggests that cranes subjected to heavy, continuous operations in challenging environments may exhibit more wear and tear than those used intermittently on lighter projects. Inspecting service records and maintenance logs can reveal critical information about the crane's operational history, helping potential buyers to make informed decisions. Understanding the nature and frequency of previous assignments can help ascertain whether the crane has been properly maintained and is capable of meeting the demands of future projects.

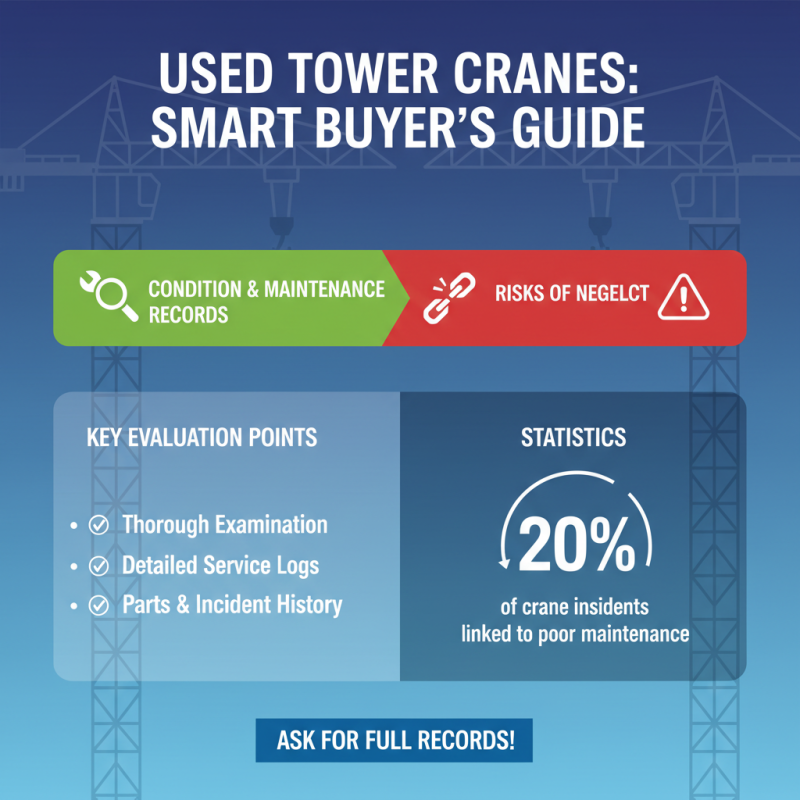

When considering the purchase of used tower cranes, evaluating the condition and maintenance records is paramount. A thorough examination of a crane's history can reveal issues that may not be immediately visible. According to a report by the International Federation of Crane Operators, around 20% of accidents in crane operations are linked to poor maintenance or neglected records. This statistic underscores the importance of scrutinizing maintenance logs for any signs of recurrent issues or significant repairs. Records should detail routine inspections, parts replacement, and any incidents that could affect the crane's performance.

Moreover, understanding usage patterns is critical in assessing the crane's condition. Industry data indicate that cranes subjected to constant heavy loads typically exhibit more wear and tear compared to those used occasionally for lighter tasks. The American Concrete Institute reports that tower cranes with robust maintenance histories can operate safely for over 20 years with proper care. Buyers should ensure that all maintenance records are complete, transparent, and indicative of a well-kept machine. This diligence will ultimately lead to better investment decisions and heightened safety on construction sites.

When considering the purchase of used tower cranes, one of the most critical factors is their load capacity and reach. Load capacity refers to the maximum weight a crane can lift, while reach indicates how far the crane can extend its jib. According to industry standards, a tower crane's load capacity can range significantly, often falling between 8 to 20 tons for mid-sized models. It is imperative that potential buyers understand the specific lifting requirements of their projects to ensure the crane can handle the workload; failing to do so could lead to operational inefficiencies or even dangerous situations.

Moreover, the reach of a tower crane directly impacts its usability on a construction site. A crane with greater reach allows for more extensive coverage, reducing the need for multiple machines and thereby optimizing workflows. Reports from industry analyses indicate that cranes with a horizontal reach exceeding 70 meters have become increasingly common on large construction projects, enabling more comprehensive site management. By evaluating both load capacity and reach, buyers can select a used tower crane that not only meets their current needs but also adapts to future demands, ensuring long-term value and safety on their construction sites.

When purchasing a used tower crane, safety features and compliance standards should be at the forefront of your decision-making process. According to the International Organization for Standardization (ISO), compliance with safety standards, such as ISO 4301, is crucial in ensuring that lifting equipment, including cranes, operates safely and effectively. This standard outlines classifications and requirements for crane operation, helping to mitigate risks associated with crane usage. Ignoring these standards can lead to significant financial liabilities and endanger the lives of workers on site.

Additionally, safety features integrated into a used tower crane can vastly improve operational reliability. A report from the American Society of Safety Professionals (ASSP) indicates that cranes equipped with advanced safety systems, such as overload protection and emergency stop mechanisms, can reduce workplace accidents by up to 30%. Features such as load monitoring systems also ensure that operators are aware of the crane's capacity in real-time, preventing hazardous overloading situations. By prioritizing safety features and compliance with recognized standards, businesses can enhance workplace safety and promote a culture of responsibility, ultimately safeguarding their workforce and assets.