In the competitive world of construction equipment, the demand for reliable and cost-effective alternatives to the Potain Used Tower Crane has never been higher. As industry expert John Walker, a seasoned construction equipment analyst, states, "Understanding the market for used tower cranes can lead to significant savings while ensuring top-notch performance." With this insight in mind, we delve into the top ten used tower cranes that present excellent value for contractors and developers alike.

The landscape of tower cranes is constantly evolving, and while Potain remains a familiar name, myriad alternatives are available that can outperform expectations without compromising on quality. In this article, we will explore the best deals on these alternatives, providing crucial information for those seeking to enhance their fleet without breaking the bank. From innovative designs to robust performance metrics, our analysis aims to highlight the most compelling options in the current market, all while keeping a sharp focus on the needs of the modern construction site.

As the demand for efficient and affordable lifting solutions grows, recognizing viable substitutes for the Potain Used Tower Crane can empower contractors to make informed decisions. Join us as we uncover the top ten used tower cranes, ensuring you have the knowledge required to make the best investment for your construction projects.

Tower cranes are an essential component in the construction industry, noted for their ability to lift heavy materials and equipment to significant heights. According to a report by Mordor Intelligence, the global tower crane market is expected to grow at a CAGR of approximately 5% from 2021 to 2026, driven by increasing investments in infrastructure and residential projects. These cranes enhance safety and efficiency on construction sites, enabling the transportation of large materials like steel and concrete with precision and reliability.

Moreover, tower cranes are particularly favored for their vertical lifting capabilities, which are crucial in densely populated urban settings where space is limited. Their ability to rotate 360 degrees allows for a wider operational range, minimizing the need for multiple cranes. The usage of tower cranes not only expedites project timelines but also reduces labor costs, as one machine can perform tasks that would otherwise require several pieces of equipment. Industry studies have shown that having a dedicated tower crane on site can increase productivity by up to 40%, making them a valuable asset in modern construction practices.

| Model | Max Load (tons) | Max Height (m) | Jib Length (m) | Year of Manufacture | Average Price ($) |

|---|---|---|---|---|---|

| TCM 6016 | 10 | 50 | 60 | 2015 | 120,000 |

| TCM 7021 | 12 | 55 | 70 | 2016 | 150,000 |

| TCM 5021 | 8 | 45 | 50 | 2013 | 100,000 |

| TCM 9024 | 14 | 65 | 75 | 2017 | 180,000 |

| TCM 1007 | 16 | 70 | 80 | 2018 | 200,000 |

| TCM 3009 | 20 | 80 | 90 | 2019 | 250,000 |

| TCM 4005 | 22 | 75 | 95 | 2020 | 270,000 |

| TCM 5008 | 25 | 85 | 100 | 2022 | 300,000 |

| TCM 6003 | 30 | 90 | 110 | 2021 | 320,000 |

| TCM 2007 | 35 | 100 | 120 | 2023 | 350,000 |

When selecting the best alternatives to Potain cranes, several criteria should be taken into consideration to ensure you make an informed decision. First, operational efficiency is crucial. According to the latest industry reports, cranes that have a higher lifting capacity and better load charts can significantly affect project timelines and costs. Models that offer quick setup and breakdown capabilities can also enhance productivity on-site, reducing downtime and improving overall performance.

Another important factor is the availability of parts and service support. A comprehensive analysis from the Crane Industry Services Association indicates that having access to a robust supply chain for spare parts and maintenance services can increase equipment uptime by approximately 20%. This is essential for minimizing disruptions during long-term projects, particularly in competitive markets where delays can lead to substantial financial losses. Consider the reputation and track record of the providers you are evaluating in order to ascertain reliability and support.

Lastly, operator comfort and safety features should not be overlooked. Research indicates that cranes with ergonomic designs and advanced safety mechanisms lead to a significant reduction in workplace accidents and injuries. Enhancing operator comfort can also improve performance, as skilled operators are able to work more efficiently when they feel secure and well-positioned. Therefore, assessing the safety record and ergonomic considerations of potential alternatives is vital in making a wise investment.

This bar chart illustrates the average lifting capacity (in tons) and rental costs (per month in USD) of the top 10 used tower cranes available as alternatives to Potain cranes.

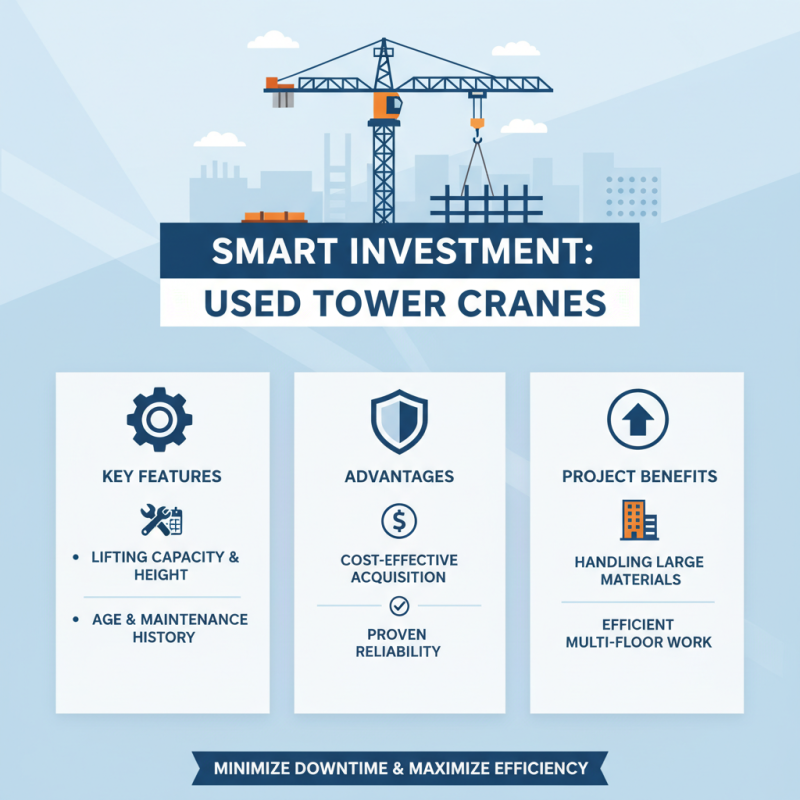

When considering the acquisition of used tower cranes, various features and advantages stand out that make them a smart investment for construction projects. One significant feature to look for is the crane's lifting capacity and height, which directly influences its ability to handle large materials and operate efficiently on multiple building floors. Many used models offer competitive specifications, ensuring they can meet the demands of even the most extensive projects. Additionally, considering the age and maintenance history of the crane can provide insights into its reliability and longevity, which are crucial factors in minimizing downtime and repair costs.

Another advantage of opting for used tower cranes is the cost-effectiveness compared to purchasing new equipment. Many used cranes come with advanced technology and robust performance characteristics, allowing buyers to benefit from high-quality equipment at a fraction of the cost. Furthermore, the availability of various configurations means that buyers can find models tailored to their specific project needs, ensuring versatility. This flexibility not only helps in optimizing project timelines but also streamlines operations by allowing teams to select cranes best suited for their tasks, greatly enhancing efficiency on the job site.

When considering alternatives to prominent tower cranes in the market, a thorough comparative analysis of pricing is essential for making informed purchasing decisions. The cost structure of these alternatives varies significantly, influenced by factors such as capacity, reach, and technology. Some tower cranes boast advanced features, such as enhanced lifting capacities and improved maneuverability, which can justify higher price points. However, there are options available that provide similar performance at a lower cost, making them attractive for budget-conscious projects.

Additionally, the quantities involved can also impact pricing dynamics. Bulk purchases often lead to discounts, while seasonal demand fluctuations can affect availability and pricing strategies. It's crucial to evaluate the total cost of ownership, including maintenance expenses and potential downtime, when comparing these alternatives. By assessing the long-term value instead of just the upfront costs, operators can identify deals that align with their operational needs and financial constraints. Exploring a variety of options ensures that construction firms can find effective solutions without compromising on quality or performance.

When considering the purchase of used tower cranes, maintenance is a critical factor that should not be overlooked. Regular maintenance ensures that the crane operates safely and efficiently, thereby prolonging its lifespan and minimizing downtime on construction sites. Potential buyers should inquire about the maintenance history of the equipment, including previous service records and any repairs undertaken. An established maintenance routine increases the reliability of the crane and helps in identifying any underlying issues before they escalate into more significant problems.

Moreover, understanding the maintenance requirements inherent to used tower cranes is essential for ensuring compliance with safety standards. Operators should be well-versed in the specific maintenance tasks necessary for the crane type they are considering. For instance, routine inspections, lubrication of moving parts, and checks on load-bearing components are vital to maintaining optimal functionality. It is also advisable to establish a proactive maintenance schedule that can facilitate swift responses to any irregularities in crane performance. By prioritizing regular upkeep, operators can achieve better performance and enhanced safety in their operations, ultimately leading to more successful project outcomes.